I came across a blog post recently in which a person says that they made a printing press simply out of an old IKEA dresser, some extra wood, and a few steel pipes. Is it true that with an old set of drawers and some extra scraps you can make your very own printing press?

Homemade printing presses

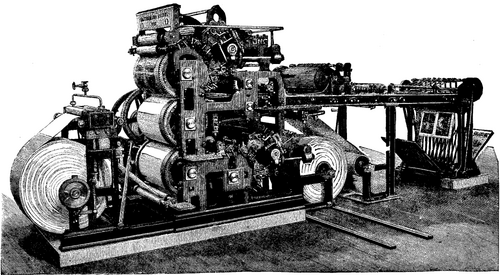

Basically, this person’s printing press, and most other homemade printing presses like it, are a much, much simpler and smaller version of the printing presses that printing and publishing companies use to create books, magazines and the like.

These homemade printing presses have very similar components to their larger, more complex counterparts. It includes an engraved printing plate that the user applies ink to. They need to push the inked printing plate against a sheet of paper to be printed, so it includes a lever to apply that pressure. There is a place to hold the paper to be printed, and a place to hold the engraved printing plate.

How does it work?

This homemade printing press that was made out of an IKEA dresser is operated very simply. The user rolls ink onto a glass plate using a rubber brayer. There is an additional piece of plywood on the sides of the dresser which holds the engraved printing plate. They use the glass plate to apply ink to the engraved printing plate.

The user attaches a piece of paper to the drawer on the inside of the press. They then slide the drawer closed to meet up with the inked printing plate. They push a lever to apply pressure to the printing plate onto the piece of paper that is to be printed on, and the print, or impression, is created.

Other homemade printing presses

If you search the internet and YouTube, you will see dozens of articles and videos about people making printing presses and letterpresses in their own homes. Most of these creators are using their home printing presses to create wedding invitations, t-shirts, etc. Some of them are very basic, like the IKEA drawer printing press. Some of them are much more complex, with electronic parts and the such, much more representative of the larger scale professional printing presses.

Will homemade printing presses replace conventional printing methods?

Just like with any industry, it seems like the home-based printing business model is gaining in popularity. Many of the creators of these homemade printing presses are marketing their services as small-scale printers. So, should larger print shops be worried?

I say no.

I think it’s a great thing that these innovators and entrepreneurs have been able to find a way to build something for themselves to make money and a small business out of. But the vast majority of these home printing presses are manual, so that greatly limits their abilities. So, they may begin to take small amounts of business from the larger printer companies in the form of small amounts of wedding or party invitations, graduation announcements, etc. But they don’t have the ability to print large amounts of prints in a small amount of time.

So, larger print shops need not worry. They will still receive the same amount of large-scale or more elaborate orders that they’ve always received. Instead of worrying about potential lost business, they should applaud these home inventors. Every industry should welcome innovation and creativity. And that is exactly what these home printing press builders and making sure to keep in the printing industry. So hat’s off to them!

This article was written by Nicole, a writer for Graphic Innovators. They specialize in the sale of new, remanufactured and quality used web offset presses and auxiliary equipment. Find a heidelberg print press.