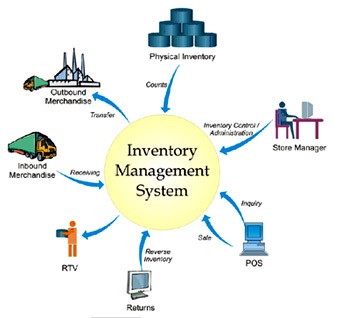

Management implies control of all the processes of supply, storage and availability of goods in order to ensure their availability at the lowest cost for storage. In practice, inventory control includes accounting reserves (both the quantity and location of goods), and optimize deliveries.

Management and Optimization

Inventory management – a pretty broad area of activity, and it can be divided into two main areas:

- “Accounting for inventories” practically cannot exist without the special software in most computerized systems. The purpose of accounting is to maintain the high productivity of all operations with inventory values.

- “Inventory optimization” means minimizing the costs (for example, for storage of unsold goods) with an unknown level of demand in the future. The aim of inventory optimization is to get the company to maximize the financial benefits of reserves.

In fact, the company’s reserves represent a single whole, but different approaches to dealing with them represent very different problems that are best solved individually.

Inventory Management

In the modern form of inventory management is almost inseparable from the appropriate software. The programs are stored electronic data on stocks that are constantly used for a quick fix of standard questions, which otherwise would have to work directly with the reserves. Ex.: “How much do we have left pieces of a certain product?”

To maintain the accuracy of the electronic inventory, all operations with the reserves should be recorded in the relevant programs. In practice, the data are usually collected by barcode or RFID identification (RFID). In modern conditions, physical operations with stocks usually automated and inventory management is carried out by means of a fully electronic.

In contrast to the accounting systems to keep accurate records of financial assets, inventory management is applied in nature and operates directly from inventory. The first objective of this system is the “productivity”, that is, all operations with material goods with the least expenditure of time and effort. The second goal is to maintain the accuracy of electronic submission of physical inventory.

Inventory Optimization

The reserves reflect the views of the demand in the future and financial relations between competing positions. If you order too many goods, sharply rising prices for storage; If the goods are too short, they quickly run out and have nothing to sell, which also lead to financial losses.

In contrast to the optimization of inventory management is also working on the best “solutions” for inventory management:

- “When and how much product you need to order”.

- “Where to store the goods” in the enterprise.

- “What goods need to be counted,” and when.

Once the decision is made, it goes through the inventory management system, but it can not be responsible for such decisions or orders to conduct manual checks by the operator.

The main problem for the optimization of inventory is the unpredictability of demand. Since the level of demand in the future is unknown, the optimization of inventories carried out on the basis of statistical forecasting methods. Decisions on “optimization” are calculated as well as solutions to minimize the “expected” costs.

Sometimes a combination of calculations further complicates optimization. For example, a business organization wants to make orders as to maximize the leverage capacity and space in the truck, reducing the cost of shipping. In practice it comes down to choosing the right balance of “heavy” and “bulk” items.

Comparison of Two Methods

As mentioned above, management and optimization of inventory – they are two different issues. The table below shows the main differences between them.

|

Management |

Optimization |

|

| Software Features | It has many functions. The more features, the higher performance, as it must take into account even the most unusual situations. | Aimed at efficiency. Quality software is measured at cost-effectiveness of the decisions issued by it. |

| Organizing effect | Awesome. Most of the operations with reserves of the company are determined directly. | Low. Operation reserves exist separately, the system simply offers options. |

| Mode | In real time. If the software is not working, the company just cannot work with their reserves. | Independent. Most decisions are sometimes one or two times a day and possibly immediately portions. |

| The computational load | Low. The inventory management software must only keep track of the physical movement of inventory as needed, and it is quite simple, taking into account the capabilities of today’s computers. | High. Software should carry out a simulation or to seek alternatives, often scanning the whole story over and over again to yield optimization solutions. |

| The replacement cost | High. Because all transactions with the reserves depends on the software. Software reflects the “state” of stocks, and it would be quite impractical to use multiple systems simultaneously, as tally sheets quickly become divergent. | Low. You can use various systems provided that the “scope” of each clearly defined. Chance of a gradual transition from one system to another. |